In the busy world of packaging, where every second counts and exactness is important , cap closing machines stand the best machine , quietly ensuring the honesty and efficiency of packaged goods. Let’s search into what cap closing machines are, why they’re essential , and how they’re shaping the packaging industry.

What Are Cap Closing Machines?

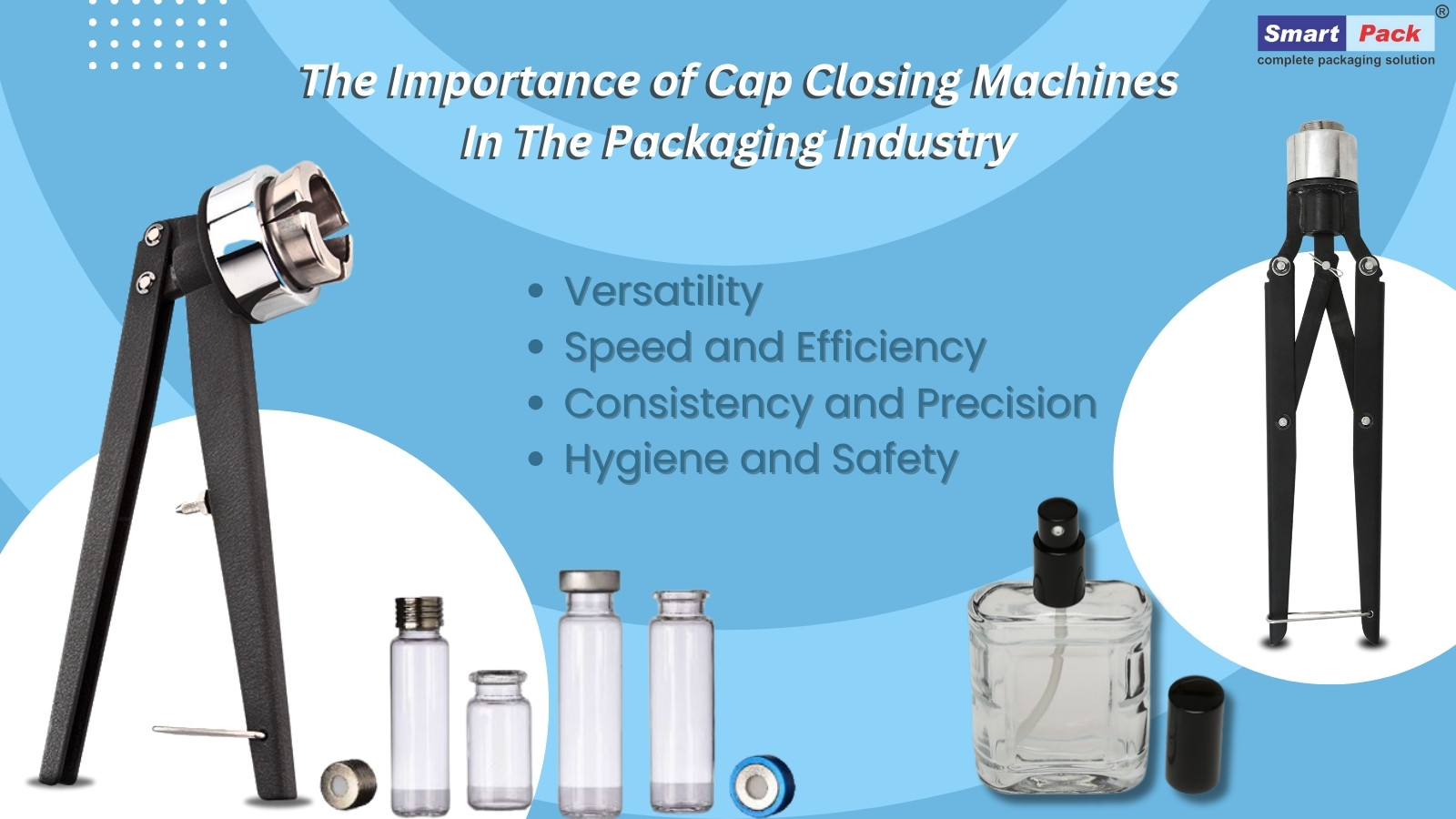

Cap closing machines, also known as capping machines, are automated devices designed to securely seal containers with caps or lids. They come in various types and sizes, serve to various packaging needs across industries. From screw caps to snap caps, these machines adeptly handle different closure mechanisms, ensuring a tight seal that preserves product freshness and prevents leakage.

Advantages of Cap Closing Machines

1. Speed and Efficiency: In the fast-paced world of manufacturing, time is money. Cap closing machines boast impressive speeds, effortlessly sealing hundreds of containers per minute. This instant operation smooths production, reducing bottlenecks and ensuring timely delivery to consumers.

2. Consistency and Precision: Humans are prone to error, but machines are constant in their accuracy . Cap closing machines deliver consistent results, tightening caps with the exact force needed to create a reliable seal every time. This uniformity enhances product quality and customer satisfaction.

3. Versatility: Whether you’re packaging beverages, pharmaceuticals, or cosmetics, there’s a cap closing machine tailored to your needs. These versatile machines accommodate various container sizes and closure types, offering flexibility across different product lines.

4. Hygiene and Safety: In industries where contamination is a concern, such as food and pharmaceuticals, maintaining a sterile environment is non-negotiable. Cap closing machines minimize human contact with products, reducing the risk of contamination and ensuring compliance with stringent safety standards.

5. Cost-Effectiveness: While the initial investment in cap closing machines may seem unsettling, their long-term benefits far outweigh the costs. By smooth production, minimizing waste, and reducing labor expenses, these machines prove to be a sound investment for manufacturers seeking efficiency and profitability.

Applications Across Industries

1. Food and Beverage: From bottled water to gourmet sauces, cap closing machines play a pivotal role in preserving the freshness and flavor of consumable goods. Whether it’s a twist-off cap for convenience or an undamaged seal for security, these machines serve the various needs of the food and beverage industry.

2. Pharmaceuticals: In the state of pharmaceuticals, accuracy is important . Cap closing machines ensure that medications remain strng and unpolluted, safeguarding patient health. Whether it’s sealing small medicine bottle, bottles, or blister packs, these machines uphold the stringent quality standards of the pharmaceutical industry.

3. Cosmetics and Personal Care: Presentation is key in the cosmetics industry, and cap closing machines deliver on both aesthetics and functionality. Whether it’s a sleek pump dispenser or an airtight jar, these machines ensure that beauty products retain their attraction and effectiveness from the factory floor to the consumer’s self-conceit.

4. Chemicals and Industrial Products: From household cleaners to automotive fluids, industrial products require robust packaging solutions that can withstand the exactness of transportation and storage. Cap closing machines provide the seal of reliability needed to prevent leaks, spills, and contamination, safeguarding both products and the environment.

Cap closing machines are the best for packaging industry, quietly ensuring the efficiency, integrity, and safety of packaged goods across diverse sectors. With their speed, precision, and versatility, these machines are not just a convenience but a cornerstone of modern manufacturing. As industries continue to evolve and consumer expectations soar, the importance of cap closing machines will only grow, driving innovation and efficiency in the dynamic world of packaging.